The highly efficient bioreactor DVZ-JZR (Jet-Zone-Reactor) represents an innovative aeration technology for sewage treatment and operates according to the injector principle.

Due to the high throughput performance and the very compact construction of the reactor this treatment technology has very low space requirements. Up to 75 % of the space requirements of a conventional sewage treatment plant can be saved by using the DVZ-JZR technology.

Its special construction without moving parts ensures zero maintenance and high operational safety.

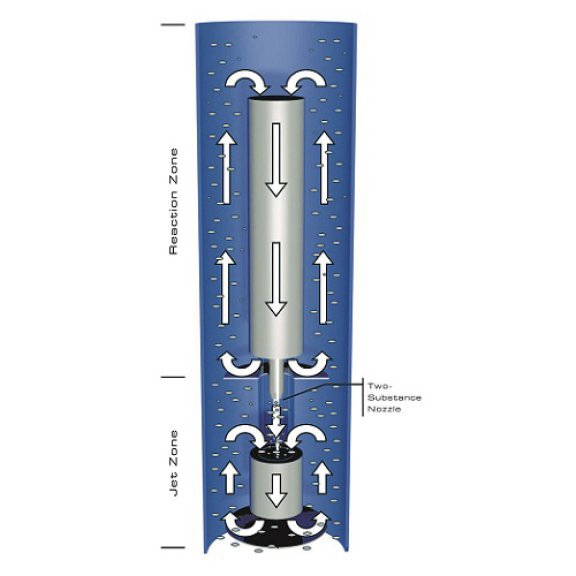

The reactor is divided into two parts: the jet zone and the reaction zone, which also determines the dwell time.

The sewage to be treated is introduced together with activated sludge via a special two-substance nozzle system with integrated aeration into the lower part of the jet zone. The bacteria contained in the waste water and the biological sewage substrate are intensively mixed with very fine air bubbles.

The multiple deflection of the medium creates a loop flow in the jet zone, resulting in optimal loading of the biomass with substrates. Part of the three-substance mixture flows from a baffle plate into the upper reactor zone (reaction zone), where the bacteria form larger floc agglomerates and react until they are exhausted.

- Optimised aeration performance per kWh, even with heavily polluted waste water

- Extremely small space requirement

- Maintenance-free and high operational safety due to special design without moving parts

- Immensely high volume-related material transfer

- Not susceptible to highly variable loadings in the waste water