The membranes of the Biomass Separation Unit “DVZ-BMSU”, which are made of a special titanium alloy, can rightly be described as almost indestructible. Due to its 100 % stainless steel construction and the deliberate avoidance of materials such as plastics and ceramics, this unique membrane technology is insensitive to high pressures and temperatures, as well as critical pH ranges. A key feature that also makes the modules of the “DVZ-BMSU” unique is “CIP” (Clean-in-Place). Here, the modules are individually decoupled from the treatment process and run through a cleaning process. During this, the sewage treatment plant remains in operation (min. two membranes).

The membrane modules are arranged outside the reactor chamber or tanks so that they are always easily accessible, easy to maintain and can be quickly replaced in exceptional cases thanks to a special quick coupling system. It is never necessary to open the treatment plant, as it is the case with submerged membranes, for example.

Due to the possibility of returning the membrane modules to “new delivered condition” through this cleaning process, an extremely long service life is realised (>20 years achievable) and the necessity of continuously changing the membranes is eliminated.

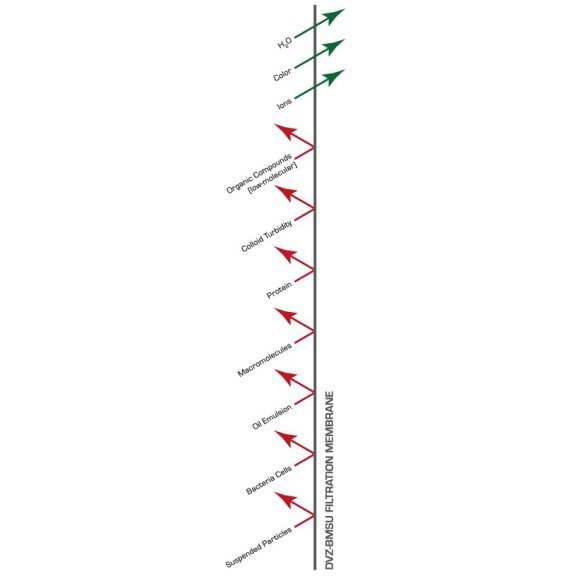

By using the “DVZ-BMSU”, which operates on the basis of the cross-flow principle, we achieve a continuous permeate quality where we consciously speak of clear water instead of “just” clean water!

The addition of disinfectants for final treatment, such as chlorine and even UV treatment, is not necessary in any case.

“DVZ-BMSU” units can also supplement existing waste water treatment plants as an additional process stage or installed downstream.